Tailings are Mine Waste

Tailings are the waste materials left after the target mineral is extracted from ore. They consist of:

- Crushed rock

- Water

- Trace quantities of metals such as copper, mercury, cadmium, zinc, etc.

- Additives used in processing, such as petroleum byproducts, sulfuric acid and cyanide.

Tailings dams

Tailings, most often in the form of a wet slurry, are conventionally stored above-ground behind earthen dams.

There is no comprehensive global registry of tailings dams. It is estimated there are around 18,000 dams, 3,500 of which are active. However, that number may be much higher. For example, China alone has more than 12,000 tailings dams.

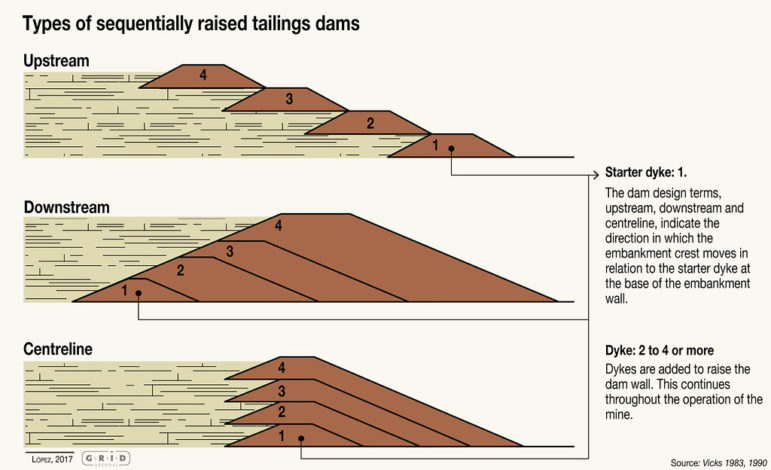

Conventional tailings dams can be built in three ways:

- Upstream: where new levels of the raises of the dam are built on top of previously-deposited tailings. This method is particularly dangerous because the underlying tailings can liquify and collapse, giving way for the whole structure to topple.

- Downstream: where new levels of the raises of the dam are built outward from the tailings and on top of previous raises. Each new level is structurally independent of the tailings and therefore considered safer than upstream dams.

- Centerline: where new levels of the raises of the dam are built on top of tailings as well as the existing embankment. This method is a combination of both upstream and downstream techniques.

The type of tailings dam a mining company builds is directly related to the safety of the structure. Engineers have found that tailings dams tend to be safest, i.e. most resistant to failure and collapse, when they are not built on top of or using previously-deposited tailings. However, the safest dams, like downstream dams, are more expensive to construct because they require more construction materials whereas upstream dams are cheaper

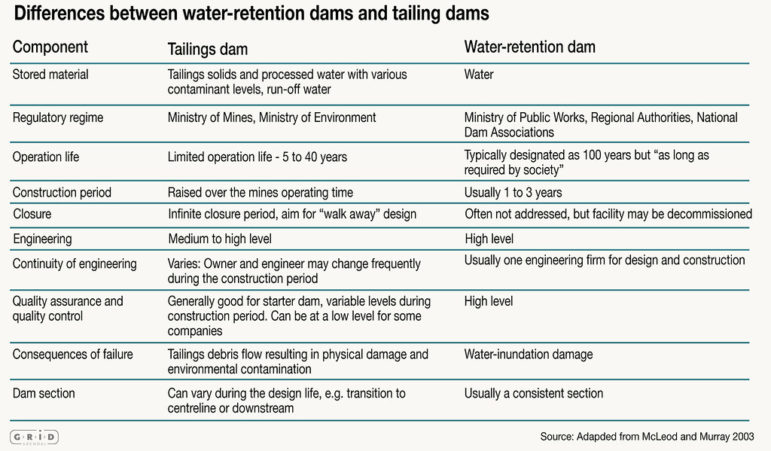

Tailings dams vs water dams

While tailings dams have similarities to water retention dams, it’s important to understand their differences in order to understand why, “tailings dams have failed at a rate that is significantly higher than the failure rate for water supply reservoir dams.”

A dam built to retain water is the final product. It is the asset. The resources used to build and maintain the dam are seen as investments in the asset. On the other hand, tailings dams serve no purpose other than to store the materials the mining company deems are waste. From an economic standpoint, mining companies have an incentive to invest as little as possible in tailings storage because the dams are not creating value. A main reason tailings dams are unsafe is because it is too expensive to build them safely and mining companies do not have an incentive to invest the resources.

Tailings dams are built gradually over time, as the mine produces more waste and hydro dams are constructed all at once. This means that safety oversight can change significantly if the mine changes operators, if the type of ore changes as the mine reaches deeper deposits, or if the mining company comes under economic pressure. For example, the Mt. Polley dam was intended to be a centerline dam but was modified during operation to use deposited tailings to support the structural core.

Alternatives to tailings dams

Besides conventional dams, there are other tailings disposal methods, including:

- Backfilling: tailings are usually combined with a binder like cement, then used to fill voids in underground operations. This is widely considered the safest form of tailings disposal.

- Filtered Tailings: (sometimes called dry stack): tailings that have a reduced water content, or “filtered”, after mill processing. The resulting tailings are like a moist soil and can be stacked in piles and compacted. However, filtered tailings can still lead to water contamination under certain circumstances.

- Aqueous Dumping: tailings are deposited directly into oceans, rivers or streams. This method is extremely destructive, polluting water, destroying ecosystems, and ruining livelihoods.

Tailings failures are increasing in frequency and severity

In August 2014, a tailings dam breach at the Mount Polley Mine in British Columbia released 5 million cubic meters of toxic waste into nearby creeks and a lake. The failure was so violent that it ripped mature trees from the forests and sent them miles downriver into Quesnel Lake.

The following year, in Brazil the Samarco Mine’s tailings dam failed catastrophically, killing 19 people downstream and sending mine waste down the Rio Doce river over 600 km to the Atlantic Ocean.

In January of 2019, after Vale vowed “never again” in response to the Samarco catastrophe, a second dam Vale collapsed, killing at least 270 people (another 11 are still missing and feared dead) and sending 9.7 million cubic meters of waste into the Paraopeba River ecosystem. An independent report commissioned in 2020 found that Vale was aware of the instability of its 86 meter tall dam as far back as 2003, but did not take appropriate measures to prevent the accident or to warn downstream communities.

Unfortunately, these failures are not aberrations. Research of all serious tailings failures since 1915 shows:

- The rate of serious tailings dam failures is increasing. Half (33 of 67) of serious tailings dam failures in the last 70 years occurred in the 20 years between 1990 and 2009.

- The increasing rate of tailings dam failures is propelled by, not in spite of, modern mining practices.The increasing rate of tailings dam failures is directly related to the increasing number of TSFs larger than 5 million cubic meter capacity necessitated to allow the economic extraction of lower grades of ore.

- 19 catastrophic failures are predicted globally from 2018 and 2027.

Aqueous tailings dumping is not the solution

In some cases, companies dump tailings into rivers, lakes and oceans. This type of disposal should be banned because:

- Tailings can contaminate aquatic life with toxic heavy metals and milling chemicals

- Some metals, particularly mercury, may bioaccumulate up the food chain, ultimately harming humans.

- It causes turbidity (murkiness from suspended particles) and reduces oxygen levels which directly impacts aquatic life.

- We simply don’t understand mine waste’s impacts on aquatic ecosystems, and it’s more difficult to control the release of contaminants.

In 2012, Earthworks and MiningWatch Canada released a report, Troubled Waters, which found that each year, mining companies dump over 180 million tonnes of these hazardous mine wastes into water bodies — more than 1.5 times the amount of waste that U.S. cities send to landfills each year.

Emphasis should be placed on reducing, recycling, and re-using metals rather than risky and irresponsible types of mine waste disposal.

How should tailings be stored?

Tailings storage facilities, especially dams, should be designed and built so that they:

- Never fail – including during the most extreme weather events imaginable in their geographic location accounting for climate change;

- Ensure safety takes precedence over cost; and

- Use best available technology and best available practices.

Specifically, safe tailings storage means:

- Never building a facility with a community or mine infrastructure in their line of failure;

- Storing the majority of tailings underground through backfilling or in mined out pits. As the Mt. Polley report highlights this requires, “integrating tailings planning into mine planning.”

- Where above ground, filtering tailings to reduce water content;

- Never storing tailings in a state where they are able to flow freely;

- Multiple redundancies of adequate liners between the tailings and the surrounding environment;

- Never using upstream dam construction;

- Never dumping tailings into local water sources;

- Continued monitoring and management by the company that owns the storage facility until it can withstand the Probable Maximum Flood and the Maximum Credible Earthquake without failure, and ability to remain in that state indefinitely.

Press Releases

South Africa Tailings Failure Shows Need for Stronger Guidelines

September 12, 2022For More Information

- Bowker and Chambers: World Mine Tailings Failures from 1915

- PBS: Tailings Dams: Where Mining Waste is Stored Forever

- Mount Polley Independent Expert Investigation and Review Report

Tailings Explained

- Mine Tailings Storage: Safety is No Accident UNEP and GRID Aredenal 2017

- The Risk, Public Liability, and Economics of Tailings Storage Facility Failures Bowker Chambers. 2015

- Root Causes of Tailings Management Failures: The Severity of Consequence of Failures Attributed to Overtopping 1915–2015 Bowker Chambers. 2016

- In The Dark Shadow of The Supercycle: Tailings Failure Risk & Public Liability Reach All Time Highs Tailings Regulations and Standards Bowker Chambers. 2017

- Tailings.info

Guidelines and Standards

- Safety First: Guidelines for Responsible Mine Tailings Management

- Global Tailings Review – Global Industry Standard on Tailings Management – August 2020

- The Australian National Committee On Large Dams (ANCOLD) – Guidelines On Tailings Dams – Planning, Design, Construction, Operation And Closure – Revision 1 (July 2019)

- Mining Association of Canada- A Guide to the Management of Tailings Facilities 3rd Edition

- The International Committee on Large Dams – Bulletins 45, 74, 97, 98, 101, 103, 104, 106, 121

- Global Mining Guidelines Group Mine Tailings: A Review of Guidelines, Initiatives and Standards

- Initiative for Responsible Mining Assurance: IRMA Standard for Responsible Mining IRMA-STD-00

Reports on Tailings Dams Failures

- Report of the Expert Panel on the Technical Causes of the Failure of Feijão Dam I -Expert Panel: Robertson, de Melo, Williams, and Wilson-December 2019

- Executive Summary of the Independent Investigation Report Failure of Dam 1 of the Córrego do Feijão Mine – Brumadinho, MG Comitê Independente de Assessoramento Extraordinário de Apuração – CIAEA February 2020

- The River is Dead: The Impact of the Catastrophic Failure of the Fundão Tailings Dam. Paul Robson for London Mining Network, 2017

- Fundão Tailings Dam Review Panel Report on the Immediate Causes of the Failure of the Fundão Dam Panel: Morgenstern, Vick, Viotti and Watts

- Independent Expert Engineering Investigation and Review Panel Report on Mount Polley Tailings Storage Facility Breach January 30, 2015

- Post-Mount Polley: Tailings Dam Safety in British Columbia. Chambers. 2016

- Reported tailings dam failures A review of the European incidents in the worldwide context Rico, et al. November 2006.

Tailings Databases

- World Mine Tailings Failures Database

- Global Tailings Dam Portal Project (self-reported by mining industry)

- Integrated Management System for Mining Dams- Brazilian Mining Agency (self-reported by mining industry)

- Chronology of Major Tailings Dam Failures– WISE Uranium Project