Pits are used to store oil and gas wastes such as produced water, fracking flowback and other liquids not captured for sale during oil and gas production. There are many potential problems from pits — leaky liners and overflows can lead to soil and water contamination, pits can produce odors and toxic air contaminants, and pits can be a hazard for birds and wildlife.

If pits are used to store oil and gas wastes, they should have, at minimum:

- two layers of liners,

- a leak detection system between the liner layers,

- fences tall and strong enough to keep out wildlife, and

- nets or other devices installed to prevent birds from coming in contact with the wastes.

Pits aren’t necessary

There are more environmentally friendly alternatives to using pits (even lined pits):

Closed Containment Systems

Oil and gas operators can use closed containment systems (e.g., tanks that are not open on top) in place of various production pits.

As with pits, it is important that tanks be enclosed by fences and nets. Otherwise, birds, wildlife and livestock may still be attracted to the liquid in the tanks.

Tanks have a tendency to corrode with time and develop leaks. And they may overflow if their capacity is not adequate to hold the wastes (and any precipitation if the tanks are not enclosed).

The New Mexico Oil and Conservation Division’s document Pollution Prevention Best Management Practices for the New Mexico Oil and Gas Industry suggests the following measures to prevent contamination from tanks. [1]

- All above ground tanks that contain fluids other than fresh water must be contained in an impermeable bermed enclosure to contain a volume of one-third more than the total volume of the largest tank or of all interconnected tanks.

- All below grade tanks. . . must have secondary containment and leak detection.

The photo of the system above (credited to USFWS) does not have adequate secondary containment. If a leak were to develop underground the wastes would seep into the soil, contaminating the soil and possibly the groundwater. The lid does adequately prevent wildlife and birds from accessing the wastes. The pipe coming out of the lid allows venting of any built-up gases in order to prevent explosions.

The tank in the photo to the right has a steel-mesh lid to keep out wildlife and birds. The secondary containment pit has prevented the fluids from flowing all over the well site, but the waste fluids have seeped into the surrounding soil. Thus, it is possible that groundwater contamination has occurred. These wastes, which may contain toxic chemicals, are now accessible to wildlife.

Benefits of closed containment systems

- Tanks require little or no maintenance.

- Tanks may be reused (moved to a new site) when the well stops producing.

- Tanks isolate waste products from the environment; if enclosed tanks are installed, there is no need to install fences or netting to keep out wildlife and livestock.

- These systems greatly reduce or eliminate soil contamination, thereby reducing remediation costs.

Examples of closed containment systems:

- In 2003, the Farmington, New Mexico City Council approved five gas wells on the condition that the company agreed to store condensate wastes in buried tanks; and install double walled condensate tanks as a means of leak protection.(Source: Laura Banish. February 12, 2003. “Farmington council approves five new gas wells,” Farmington Daily Times).

- Many well sites in New Mexico use tanks to hold production wastes, but most lack leak detection devices and adequate secondary containment systems.

In the photo to the right, the tank has a solid top to prevent wildlife access. But there is no secondary containment system to prevent any fluids that overflow from seeping into the soil, and there is no way to easily detect if the bottom of the tank is leaking.

Closed-loop or “Pitless” Drilling Systems

During drilling operations, “closed-loop” drilling fluid systems (sometimes referred to as “closed mud” or “pitless” systems) can greatly reduce or eliminate the discharge of toxic drilling wastes on site. These systems negate the need for drilling reserve pits. Not only is it possible to have pitless drilling operations, it can also be an economic advantage to companies to used closed-loop drilling systems.

Many companies are using closed loop drilling systems in Texas, Louisiana, Oklahoma, Alaska and other states. Examples of companies who are using closed-loop technologies include: Shell, El Paso, Chevron-Texaco, Exxon, and many others.

Differences between conventional drilling and closed-loop drilling systems

At a typical oil or gas drilling site, drilling fluids (mud, water, additives) are circulated through the wellbore, then the fluids and drill cuttings (rock fragments created by the drilling process) are deposited in a reserve pit dug near well. This pit is used to hold used drilling fluids and wastes.

A reserve pit can be the source of considerable costs at a drilling site.

- The pit itself must be constructed at the beginning of drilling, which requires the use of heavy earthmoving equipment.

- The pit may have to be lined.

- When the drilling project is over, the pit, including all of the waste fluids and solids, must be properly remediated. Remediation could include activities such as: the removal and offsite disposal of the waste materials and liner; the burial of the wastes and liner; backfilling of the pit with soil; and revegetation of the disturbed pit area.

Also, there are health, environmental, and financial risks associated with pits, which can contaminate soils with hydrocarbons, metals and salts, and leak potentially toxic liquids into surface or groundwater. [2]

In a closed-loop drilling fluid system, the reserve pit is replaced with a series of storage tanks that separate liquids and solids. Equipment to separate out solids (e.g., screen shakers, hydrocyclones, centrifuges) and collection equipment (e.g., vacuum trucks, shale barges) minimize the amount of drilling waste muds and cuttings that require disposal, and maximize the amount of drilling fluid recycled and reused in the drilling process. The wastes created are typically transferred off-site for disposal at injection wells or oilfield waste disposal facilities.

The tanks represent an additional cost, but overall, pitless drilling can save an operator money because there is no need to construct a pit, there is a reduction in the amount of environmental releases, and the closed-loop system results in more efficient use of drilling fluid.

Benefits of Pitless Drilling:[3]

- it eliminates unsightly and hazardous pits

- it reduces the time, energy and expense of building, fencing and reclaiming reserve pits

- it decreases the need for cuts in sensitive and hilly areas

- total surface disturbance associated with a well pad is reduced

- it eliminates risk of waterfowl and wildlife mortality related to pits

- it eliminates risk of damaging underground pipelines and utilities

- it allows drilling in areas with a high ground water table

- it virtually eliminates drilling waste

- rigs use less water per well – it can reduce water consumption by as much as 80%

- the US Environmental Protection Agency (EPA) has estimated that “closed loop systems” can reduce the volume of drilling fluids by as much as 90% [4]

- it eliminates soil segregation, which reduces wind erosion problems

- it reduces truck traffic associated with transporting drilling wastes by as much as 75%

- it may improve relationship with surface owners

- it greatly reduced waste tracking and need for land farming operations

- drill cuttings may be put to beneficial use, e.g., if not contaminated they may provide a source of finely-ground clay for berm construction around tank batteries or other uses

- the tanks can be re-used

Closed-loop systems reduce company liability

Pits may or may not be lined (depending on the oil and gas regulations); and pits are open to the atmosphere. Because of this, the pit may leak liquids into surface or groundwater and release high levels of volatile organic compounds, which in turn create health, environmental, and financial risks. If improperly fenced, livestock may enter the pit area. If the livestock is poisoned by the pit materials, companies may be liable for the deaths, and be required to compensate the livestock owner.

According to the Railroad Commission of Texas, even though closed-loop drilling is not always the least expensive option, some companies in Texas have elected to use only closed-loop drilling fluids systems in their operations. Why? Because whenever a closed-loop system is used, the operator reduces the potential future liability associated with a conventional earthen pit, and reduces the waste management and site closure costs. It’s also good for the company image and public relations.

Increased Utilization of Closed-Loop Drilling

According to a paper entitled “Bulk Transportation of Drilling Wastes,” delivered at an American Association of Drilling Engineers Conference in 2002:

. . .environmental concerns and regulatory authorities are forcing the offshore drilling industry to modify or eliminate dumping of drilling wastes overboard. On land rigs, the practice of constructing earthen reserve pits is also declining in favor of ‘zero-discharge’ closed-loop systems. Therefore the effective containment and transportation of drilling wastes is becoming ever more important. The environmental benefits of a well designed waste collection and transportation system can be observed directly in many cases.[5]

The New Mexico Oil Conservation Division identifies closed-loop drilling as a “best management practice” in their Pollution Prevention Best Management Practices for the New Mexico Oil and Gas Industry. (See footnote 1) New Mexico OCD is not alone in identifying closed-loop drilling systems as a best practice. In almost any pollution prevention or “Best Management Practices” document for the oil and gas industry, closed-loop drilling systems are mentioned as the most environmentally safe method for reducing the potential impact that drilling operations can have on the environment. For example, the practice is mentioned in the following documents:

- The Illinois Environmental Protection Agency’s Best Management Practices for Oil Exploration and Extraction

- Railroad Commission of Texas’ Waste Minimization in Drilling Operations

Increasingly, closed loop systems are being used all over the United States, Canada, and the world. In personal conversations with closed-loop drilling system companies, OGAP has heard that one company has performed approximately 900 closed-loop drilling operations in the past eight years (in CO, WY, ND, NM and other western states). A representative from another company operating out of Texas, Louisiana and Oklahoma remarked that most of the major companies in the region are using closed-loop drilling systems at the majority of their operations, because they understand the potential future liabilities that may follow them if they use conventional drilling systems that use reserve pits.

This information was corroborated by the Texas Railroad Commission, which stated that, “Even though it is not always cost effective, some companies have elected to use only closed loop drilling fluid systems in their operations. . .whenever a closed-loop system is used, the operator reduced his potential liability associated with a conventional earthen pit and waste management and site closure costs.” [6]

According to the U.S. Congress, Office of Technology Assessment, these systems are increasingly being used (e.g., in California) because of the reduction in overall drilling costs and in the volume of wastes needing disposal. (See footnote 4)

Comparison of closed-loop systems versus pits

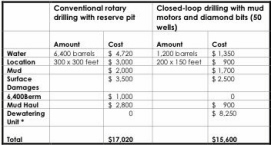

CASE 1: Prima Energy’s Cost-Benefit Analysis [7]

Prima Energy Corp. has drilled more than 68 wells in Colorado using a highly automated closed-loop system, which the company started developing along with Nabors Drilling USA, Inc. in 1993. The company found that the economics of drilling these wells in Colorado were best if drilling required less than 12 days.

The table below provides a summary of the economics of using conventional reserve pits versus closed-loop drilling systems.

* Dewatering cost includes rental of unit, labor, extra fuel, polymer and acid,

linear motion shaker, centrifuge, trucking, end loader and miscellaneous costs.

Prima Energy’s calculated benefits of closed-loop drilling:

- cost savings of $1,320 per well

- water savings of 5,200 barrels (closed-loop drilling used 80% less water)

CASE 2: MiSWACO – Closed-loop vs. Conventinal Systems: A tale of two wells [8]

Closed-loop systems employ a suite of solids control equipment to minimize drilling fluid dilution and provide the economic handling of the drilling wastes. For one company, a typical closed-loop system includes a series of linear-motion shakers, mud cleaners and centrifuges followed by a dewatering system. The combination of equipment typically results in a “dry” location where a reserve pit is not required, used fluids are recycled, and solid wastes can be landfarmed, hauled off or injected downhole.

Two wells, drilled only 200 ft apart in Matagorda County, TX, provided a unique opportunity to compare the cost savings difference between conventional solids-control equipment and the company’s closed-loop system. Both wells drilled through the same formations, using the same rig crew, mud company and bit program.

The closed-loop system with improved solids control resulted in some significant savings:

- 43% savings in drilling fluid costs

- 23% fewer rotating hours

- 33% fewer days to drill to a comparable depth

- 37% reduction in the number of bits used

- up to 39% improvement in the rate of penetration

CASE 3: Reducing Waste Volume and Costs Using Closed-loop Systems [9]

Challenges: Challenges associated with conventional reserve pits include volume of drilling wastes; drill site installation and restoration costs; pollution of land and/or surface water due to failure of pits and/or containment system and associated cleanup costs; and potential for subsurface pollution due to downward migration from pits and/or surface soil permeability.

Solution: Use closed-drilling pit system to reduce volume of drilling waste. The drilling contractor maintained “safe pit levels” and recycled drilling fluid to minimize pit volumes and disposal requirements. Waste management costs due to procedures other than those specified were also the responsibility of the drilling contractor. Cost savings provided the incentive to implement and maintain proper procedures to minimize waste generation in the closed-loop system.

|

Conventional reserve pit |

Closed-loop drilling | |

|

Surface disturbance |

reserve pit (235′ x 77′ x 5′) |

No reserve pit necessary. |

|

Total drilling mud and wastes |

16,625 barrels |

1,100 barrels |

|

Total reduction in drilling mud and wastes in pits using closed-loop drilling |

15,625 barrels |

Benefits: The following benefits were realized:

- Total estimated cost savings (considering reduced costs for drill site installation, fluid hauling and disposal, dirt work, and surface damage payment): $11,000.00

- Reduced surface disturbance by 18,000 square feet (0.4 acres).

- Reduced drilling mud and wastes in pits by 15,625 barrels.

- Reduced potential for environmental impact to surface and groundwater.

CASE 4: Closed Loop Drilling Fluid System [10]

Problem: A small independent operator was concerned about the volume of drilling waste in conventional reserve pits at his drilling locations. Waste management costs were a concern, as well as the costs associated with impact on adjacent land due to pit failures. The operator was concerned about the potential for surface water or ground water contamination and the associated potential liabilities.

Solution: The operator was drilling relatively shallow wells in normally pressured strata. Because the drilling plan was relatively simple, the operator investigated the feasibility of using a closed-loop drilling fluid system for these wells. The use of a closed-loop system eliminated the need for a conventional reserve pit. The operator negotiated with drilling contractors to obtain a turn-key contract that required the drilling company to use a closed-loop system and take responsibility for recycling the waste drilling fluid.

Benefits: The turn-key contract was incrementally more expensive. Yet, because of reduced drill site construction and closure costs; reduced waste management costs; and reduced surface damage payments, the operator realized a savings of about $10,000 per well. Also, the operator reduced the potential for environmental impact and associated potential liability concerns.

CASE 5: Closed-loop System Helps Reduce Drilling Waste [11]

A large oil and gas production company used a number of pollution prevention techniques, including closed loop drilling, to drill an exploratory well adjacent to the Tishomingo Wildlife Refuge in Johnston County, OK. The well was drilled on land owned by the U.S. Army Corps of Engineers. Some of the measures taken in drilling the well included:

- Using a closed-loop mud system that allowed for reuse of drilling fluids and use of smaller quantities of water for dilution of the mud to control viscosity and density

- Use of compressed air as the drilling fluid where possible, which allowed for the use of smaller quantities of water and drilling fluid

- Using a smaller casing, which allowed for the use of a 25% smaller hole. This generated a smaller volume of drill cuttings and required less drilling fluid

Savings and Benefits: The hole-size reduction, use of air drilling and closed-loop system reduced wastes by close to 1.5 million pounds. A material and disposal cost savings of $12,700 was achieved.

For More Information

Sources:

- New Mexico Oil Conservation Division (OCD). Pollution Prevention Best Management Practices for the New Mexico Oil and Gas Industry. Volume I, Section 6, pp. 49, 50. Available for download from the OCD web site.

- U.S. Environmental Protection Agency (U.S. EPA). October, 2000. Profile of the Oil and Gas Extraction Industry. EPA Office of Compliance Sector Notebook Project. EPA/310-R-99-006. p.69.

- Longwell, John. Prima Energy Corp; and Glenn Hertzler, Nabors Drilling USA, Inc. “Closedloop system as a cost effective alternative to reserve pits.” Presentation to the Consortium for Emerging Gas Resources in the Greater Green River Basin, Advances in Drilling Technologies for the North American Rockies (Denver, Colorado, April 28, 1997).

- U.S. Congress, Office of Technology Assessment. March, 1992. Managing Industrial Solid Wastes from Manufacturing, Mining, Oil and Gas Production, and Utility Coal Combustion. Background Paper, OTA-BPO-82. (Washington, DC: U.S. Gov. Printing Office). p. 75

- Richards, M.J. and Love, W.W. 2002. “Bulk Transportation of Drilling Waste,” a paper presented at the American Association of Drilling Engineers 2002 Technology Conference, April 2002, in Houston, TX. Paper AADE-O2-DFWM-HO-18.

- Railroad Commission of Texas. Oil and Gas Division. Waste Minimization in Drilling Operations.

- Longwell, John and Hertzler, Glenn. (Prima Energy Corp. and Nabors Drilling USA, Inc., respectively). 1997. “Closed-loop system as a cost effective alternative to reserve pits,” presented at the Advances in Drilling Technologies for the North American Rockies Conference (April 28, 1997, Denver, CO); and Interstate Oil and Gas Conservation Commission. 1999 Chairman’s Stewardship Award Report.

- M-I SWACO. “Swaco closed loop systems: A tale of two wells.” This is Swaco. p. 3

- New Mexico Oil Conservation Division (OCD). Pollution Prevention Best Management Practices for the New Mexico Oil and Gas Industry. Available for download from the OCD web site.

- Railroad Commission of Texas. Waste Minimization – Case Histories – Drilling Operations.

- Oklahoma Department of Environmental Quality. Pollution Prevention Case Studies.