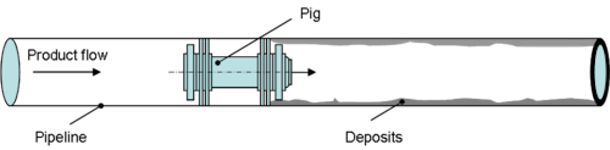

The oil and gas industry inspects and cleans pipelines by “pigging.”

The name originates from either Pipeline Inspection Gadget, or the squealing sound pigging tools make as they pass through the pipeline.

“Pigs” are made of different durable materials, and more advanced “smart pigs” are essentially robots capable of detecting leaks and corrosion.

Pigging stations may be integrated with gas processing plants, co-located with compressor stations or independently sited along pipelines.

If a natural gas pigging station is located prior to a processor along the pipeline, pigging can remove and separate liquids—a process that the US Environmental Protection Agency indicates can result in the venting of hydrocarbons into the air. Pigging also releases methane and other pollutants through leaking valves and equipment.

When the Federal Energy Regulatory Commission (FERC) reviews interstate gas pipeline projects, pigging operations are included in the project plans. Because pigging is generally considered to be part of the pipeline system or compressor station operations, they aren’t permitted separately and their oversight falls to pipeline companies, oil and gas operators, and utilities.